MISUMI Group Inc. (“MISUMI”; Head Office: Chiyoda-ku, Tokyo; Representative Director and President: Ryusei Ono) has begun providing Third-Party Logistics (3PL) services to PUNCH INDUSTRY CO., LTD. (“the Punch Group”; Head Office: Shinagawa-ku, Tokyo; Representative Director, President and CEO: Tetsuji Morikubo) as of October 2025. In conjunction with this launch, the logistics operations of both companies have been consolidated at MISUMI’s East Japan Distribution Center in Kawasaki, Kanagawa.

The consolidation of logistics hubs is intended to create scale advantages by integrating the shipment volumes of both organizations, while also enhancing operational efficiency through the utilization of MISUMI’s advanced automation equipment. Through this initiative, MISUMI aims to further strengthen its capabilities to deliver products to customers in a stable and sustainable manner.

This initiative―“Monozukuri B-to-B Business: Joint Inventory Management and Transportation Project”―was advanced jointly by the three companies, MISUMI, the Punch Group, and SBS Sokuhai Support Co., Ltd. (Head Office: Koto-ku, Tokyo; Representative Director and President: Masahiko Kamata). It has also been selected by Japan’s Ministry of Economy, Trade and Industry (METI) for its “Demonstration Project for Logistics Efficiency to Support Sustainable Logistics (1) Collaborative Demonstration Projects Contributing to Logistics Efficiency.”*1 The Demonstration Project was completed at the end of January 2026, achieving improved operational efficiency through the advancement of warehouse automation.

1* METI “Demonstration Project for Logistics Efficiency to Support Sustainable Logistics”

https://logiefficiency-meti.jp/r6h/

MISUMI and the Punch Group will continue to contribute to optimizing the supply chain across the metal processing and mechanical components industries by addressing industry-wide challenges such as shortages in transportation capacity and rising logistics costs.

Exterior view of MISUMI’s East Japan Distribution Center in Kawasaki, Kanagawa

Purpose and Outlook of This Initiative

Purpose and Outlook of This Initiative

Through the capital and business alliance concluded on October 7, 2024, MISUMI and the Punch Group agreed to leverage both companies’ resources effectively and jointly pursue the growth and development of the metal processing and mechanical components industries. The consolidation of logistics hubs announced in this initiative is part of that collaboration, and represents the MISUMI Group’s first case of providing logistics services to an external company.

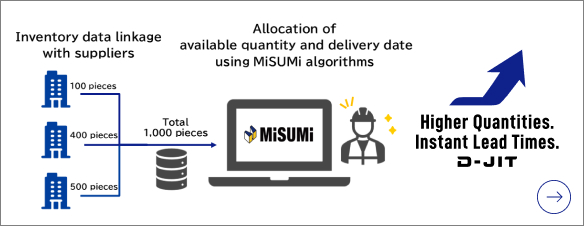

By consolidating the shipment volumes of both companies, the initiative has delivered meaningful scale efficiencies. The integration of logistics operations reduced truck waiting and loading times by 110 hours per month and eliminated the equivalent of 216 ten ton truck trips per month.*2 Within the distribution center, MISUMI is also advancing automation through the deployment of shelf transport robots and automated counting and picking carts. Together, these measures have improved logistics productivity and reduced operating costs.

MISUMI operates a robust logistics platform that handles more than 30 million items and reliably supplies products to 323,000 customers worldwide. The Company’s logistics excellence has been recognized across the industry, including receiving the highest honor—the Best Logistics Improvement Award (Logistics Operations Category)—in the “2025 Logistics Improvement Awards” presented by the Japan Institute of Logistics Systems (JILS).*3

Looking ahead, MISUMI and the Punch Group plan to enhance cost competitiveness by leveraging scale through initiatives such as joint procurement of inventory and mutual supply of products. The companies also intend to expand collaboration in growing overseas markets, combining the Punch Group’s precision machining capabilities and customer responsiveness with MISUMI’s digital capabilities and global supply capacity.

2* Actual results as of January 2026

3* JILS News Release: “Winners of the 2025 Logistics Improvement Awards”

https://www1.logistics.or.jp/news/news-9112/

PUNCH INDUSTRY CO., LTD. Overview

PUNCH INDUSTRY CO., LTD. Overview

- Company Name

-

PUNCH INDUSTRY CO., LTD.

- Representative

-

Tetsuji Morikubo, Representative Director, President and CEO

- Head Office

-

Omori Bellport E-5F, 6-22-7 Minami-oi, Shinagawa-ku, Tokyo 140-0013

- Listing

-

Tokyo Stock Exchange Standard Market (6165)

- Founded

-

1975

- Net Sales

-

JPY 40.8 billion (Consolidated, fiscal year ended March 2025)

- Employees

-

3,463 (Consolidated, as of March 2025)

- URL

- Business Description

-

Manufacturing and sales of mold and die parts, automation equipment and related components, and custom mechanical parts

About MISUMI

About MISUMI

MISUMI provides mechanical components as well as tools, consumables, and other related products required at Monozukuri sites, serving over 323,000 companies globally (as of March 2025). Our unique Business MODEL—which combines in-house manufacturing and distribution of third-party products, and supported by a robust Business Foundation, we achieve “Globally Reliable and Quick Delivery,” thereby contributing to enhanced customer convenience.

For inquiries regarding this press release, please contact:

T. Shoda and W. Nishizaki

Corporate Relations Department

MISUMI Group Inc.

Tel: +81-3-6777-7502

Email: pr@misumi.co.jp

MISUMI's e-Commerce Site

We supply custom parts for automation devices and equipment, dies/molds, tools, consumables, and more, with same-day shipping at the earliest. Products from more than 3,000 domestic and international third-party brands, including MISUMI, are offered.