As of October 7, meviy, an AI-based parts procurement platform (powered by MISUMI Group Inc.) offers "Vacuum Quenching", "Induction Hardening" and "Hardness Specification" services for CNC turning (round objects). This allows for increased wear resistance of parts, hardening of drivetrain components that require both hardness and toughness, and selective hardening of the area adjacent to the workpiece.

MISUMI will continue to provide time value to our global customers in the IA (Industrial Automation) industry through expanding our services and contribute to enhancing their productivity.

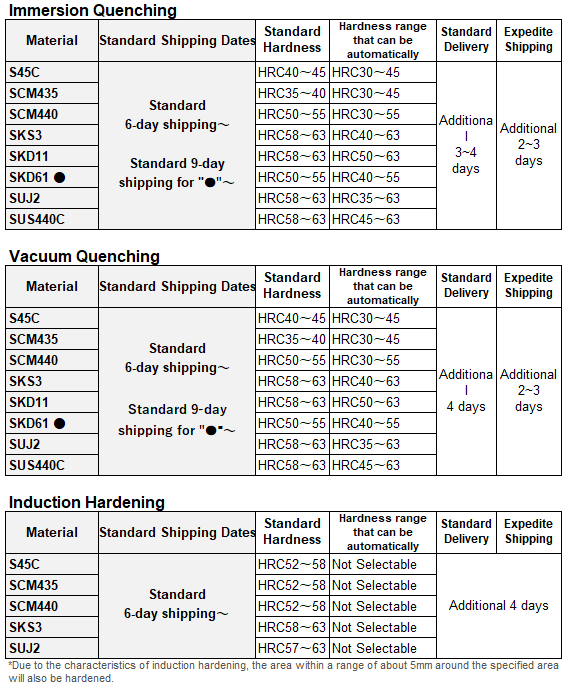

From left: Immersion Quenching, Vacuum Quenching, and Induction Hardening

Background

Background

As part of our efforts to improve meviy, we have worked to shorten the lead time for quenching services, and currently offer Immersion Quenching for CNC turning. On the other hand, there were many customer requests for hardening, such as "I want to specify the hardening method according to application", "I want to specify Vacuum Quenching which has higher wear resistance", and "I want only certain areas (of a part) to be hardened".

To respond to these requests, we have newly added "Vacuum Quenching*1", "Induction Hardening*2" and "Hardness Specification" services.

These new services, which allow customers to specify the hardened areas and hardness level, were made possible through system development and establishment of a hardening production system. As a result, customers can now procure parts that were previously unavailable via meviy, such as drivetrain components that require both hardness and toughness. We now expect meviy to be used in a wider variety of customer situations.

- ※1

-

"Vacuum quenching" is a type of heat treatment method that involves heating in a vacuum environment followed by rapid cooling, which improves the durability and hardness of metals. Compared with "Immersion quenching", which is carried out in the atmosphere, heating in a vacuum environment suppresses oxidation and surface deterioration, keeping the product surface clean.

- ※2

-

"Induction hardening" is a heat treatment method that uses high-frequency waves to harden only certain parts of metal components. It hardens only the necessary parts by heating only those parts that require particularly high strength and wear resistance, and then rapidly cooling them.

Service Release Overview

Service Release Overview

- Release date:

-

October 7, 2024

- Service eligible for:

-

CNC turning (round products)

- Newly added services:

-

Vacuum Quenching, Induction Hardening, and Hardness Specification

To learn more about our hardening services available for CNC turning (round parts), please see the following.

▼meviy Service Website Information (in Japanese)

https://jp.meviy.misumi-ec.com/info/ja/news/new-release/45327/

Possible shipping dates by materials eligible for the new services

Possible shipping dates by materials eligible for the new services

About meviy

About meviy

With meviy, customers simply upload a 3D model of a mechanical component, the AI automatically provides an instant quote, and our unique Digital Manufacturing System enables an order to be shipped in one day at the earliest.

meviy is a platform that eliminates perceived inefficiencies in parts procurement by reducing the time customers traditionally spend procuring mechanical components by more than 90%.

meviy received the Prime Minister's Prize at the Ninth Monodzukuri Nippon Grand Awards, achieved the No. 1 market share in Japan for three consecutive years, and is highly regarded for its contributions to improving productivity in the manufacturing industry. For our global customers, the range of services on each meviy website is expanding. meviy delivers "time value" to customers worldwide through digital transformation in component procurement.

About MISUMI

About MISUMI

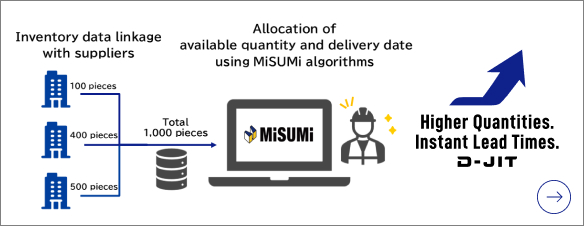

MISUMI sells mechanical components required on-site for factory automation, as well as tools, consumables, and other products to more than 318,000 companies (as of March 2024) worldwide. We wear two hats: a manufacturer with manufacturing functions and a distributor of other company’s branded products.

With this unique business model, supported by a solid business foundation, MISUMI achieves "globally reliable on-time delivery" for greater customer convenience.

【For inquiries regarding this press release】

Please contact Y. Matsubara or K. Koniwa

e-mail: pr@misumi.co.jp

Tel: 03-6777-7502

Corporate Relations Department

MISUMI Group Inc.

MISUMI's e-Commerce Site

We supply custom parts for automation devices and equipment, dies/molds, tools, consumables, and more, with same-day shipping at the earliest. Products from more than 3,000 domestic and international third-party brands, including MISUMI, are offered.