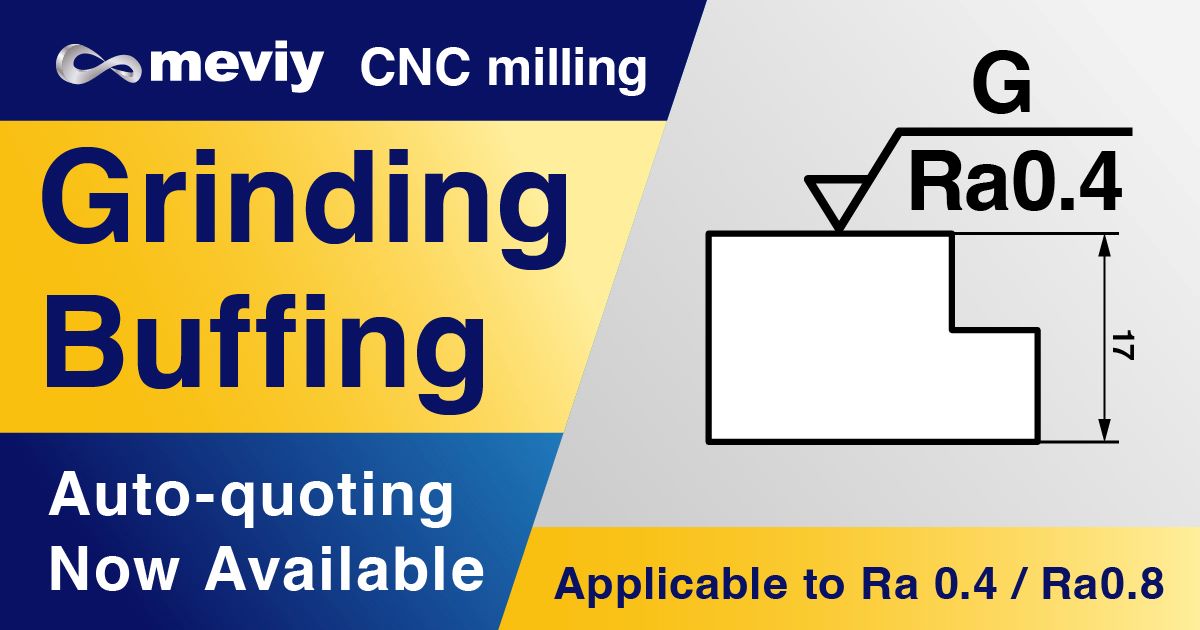

Starting January 20, 2024, auto-quoting for grinding and buffing in CNC milling (squared parts) will become available at meviy, an AI-based parts procurement platform powered by MISUMI Group Inc. (Headquarters: Chiyoda-ku, Tokyo, Japan; Representative Director and President: Ryusei Ono). Demand for high-precision products accounts for approximately 25%*1 of all CNC milled (square) parts used as machine parts. The introduction of this new feature will enable the auto-quoting for high-precision parts, which will greatly expand meviy's range of services and making it possible to meet a wider range of parts procurement needs.

We will continue to provide time value to our global customers in the IA (Industrial Automation) industry through expanding our services and contribute to enhancing their productivity.

- *1

-

Calculated based on the results of a customer survey conducted by meviy.

About Griding and Buffing

About Griding and Buffing

Grinding and buffing are both types of surface finishing that increase the fineness of surface roughness. They are used to improve the sliding properties of parts, improve sealing, and prevent the adhesion of dirt.Grinding is a machining process that uses a grinding wheel to grind a workpiece. A grinding wheel rotating at high speed is pressed against the workpiece to gradually remove the surface of the workpiece. Another thing to note about this process is that it is used as the final finish of machining and other meviy, an AI-based parts procurement platform Auto-quoting Now Available for Grinding and Buffing in CNC Milling - High-precision machining, an in-demand feature, supporting surface roughness to Ra 0.4 - processes. Buffing, on the other hand, is a process that polishes and smoothes metal surfaces by rotating a "buff" made of cloth, leather, urethane, or other material.

Background

Background

Grinding and buffing are in great demand, accounting for about 25%*1 of the milled (square) parts in the market. We have received many requests from our customers for auto-quoting for grinding and buffing, and now we have now achieved this by developing this feature in the high-precision field and enhancing our production system.

High-precision parts, which used to be machined by meviy but had to be outsourced separately for grinding and buffing, can now be arranged in a single process from quotation to order by meviy, allowing customers to utilize meviy in a wider range of situations.

Service Overview

Service Overview

- Release Date

-

January 20, 2024

- New Feature

-

Iron, SUS, aluminum (*Flat bar, Parker treatment, black alumite (matte finish) are not applicable.

- Supported surface roughness

-

Ra0.4 to Rz1.6

- Supported dimensional and external tolerances

-

Supported dimensional and external tolerances

- Delivery time

-

+ 4 days for Standard, + 4 days for Long

- *

-

Not applicable to Ultra-short Delivery and Short Delivery Services.

Please see the following for details of the new feature.

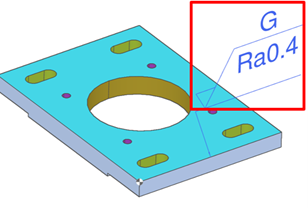

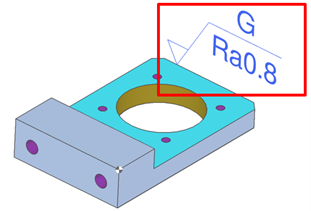

Shapes and setting locations examples

Shapes and setting locations examples

Motor bracket (grinding instruction: G-Ra0.4)

Bearing holder (grinding instruction: G-Ra0.8)

About meviy

About meviy

With meviy, customers simply upload a 3D model of a mechanical component, the AI automatically provides an instant quote, and our unique Digital Manufacturing System enables an order to be shipped in one day at the earliest.

meviy is a platform that eliminates perceived inefficiencies in parts procurement by reducing the time customers traditionally spend procuring mechanical components by more than 90%.

meviy received the Prime Minister's Prize at the Ninth Monodzukuri Nippon Grand Awards, achieved the No. 1 market share in Japan for three consecutive years, and is highly regarded for its contributions to improving productivity in the manufacturing industry. For our global customers, the range of services on each meviy website is expanding. meviy delivers "time value" to customers worldwide through digital transformation in component procurement.

About MISUMI

About MISUMI

MISUMI sells mechanical components required on-site for factory automation, as well as tools, consumables, and other products to more than 320,000 companies*2 worldwide. We wear two hats: a manufacturer with manufacturing functions and a distributor of other company’s branded products. With this unique business model, supported by a solid business base, MISUMI achieves "globally reliable, quick delivery" for greater customer convenience. (*2 As of March 2023)

For inquiries regarding this press release, please contact

Matsubara, Corporate Relations Department MISUMI Group Inc.

- Tel

-

03-6777-7502

MISUMI's e-Commerce Site

We supply custom parts for automation devices and equipment, dies/molds, tools, consumables, and more, with same-day shipping at the earliest. Products from more than 3,000 domestic and international third-party brands, including MISUMI, are offered.