MISUMI Group Inc. (Headquarters: Chiyoda-ku, Tokyo, Japan; Representative Director and President: Ryusei Ono) held a “meviy Factory Day” at the Shimizu Factory of SURUGA Production Platform Co., Ltd. (Headquarters: Shizuoka City, Shizuoka Prefecture, Japan; Representative Director and President: Takumi Toya). At this grand event, the unmanned production lines of meviy, an AI-based machine parts procurement platform, and its digital manufacturing system were unveiled to the media for the first time. A large number of attendees were welcomed, including representatives from companies using meviy in Japan and abroad, and Professor Takahiro Fujimoto of the Institute for Business and Finance, Waseda Business School, an authority on manufacturing in Japan.

Purpose of the Event

Purpose of the Event

At the meviy Factory Day, the meviy Digital Manufacturing System (developed in-house), an innovation on par with meviy's AI auto-quoting, was presented to the media for the first time. MISUMI has already developed the MISUMI Production System, which produces 800 sextillion (8 billion times one trillion) product variations with short delivery times. Based on the MISUMI Production System, the meviy Digital Manufacturing System supports its digital manufacturing, and realizes reliable, quick delivery for variable mix and quantity production that is technically challenging. To make this core innovation of meviy widely known, we have made the back-end production system open to the media for the first time.

Event Overview

Event Overview

- Event Name

-

meviy Factory Day

Digital Manufacturing System: Another Innovation on a par with AI Auto-Quoting

- Sponsored by

-

MISUMI Group Inc.

- Date & Time

-

Friday, January 26, 2024, 09:40-13:40

- Location

-

Shimizu Factory, SURUGA Production Platform Co., Ltd.

(Address: 505 Nanatsushinya, Shimizu-ku, Shizuoka City, Shizuoka Prefecture, Japan)

- Attendees

-

Media (Newspapers, magazines, and web media), analysts, manufacturing experts, and meviy users

Event Report

Event Report

<Presentation by our corporate officers>

<Presentation by our corporate officers>

Two presentations were given by MISUMI executives, namely Mitsunobu Yoshida, Senior Corporate Officer of MISUMI Group Inc. and President of its ID Business Company, and Takumi Toya, President and Representative Director of SURUGA Production Platform Co., Ltd.

"This is the first time we’re showing the more important of the two meviy innovations - how our digital manufacturing works. I'm sure you'll enjoy it." With these words, Yoshida began his presentation. He also talked about the challenges facing the Japanese manufacturing industry and the social role and mission that meviy plays in the sustainable development of the industry.

Toya explained the evolution of digital manufacturing that MISUMI has cultivated over the years, including the MISUMI Production System.

“Revolutionizing Manufacturing with meviy,

a digital transformation in manufacturing”

Mitsunobu Yoshida, Senior Corporate Officer of MISUMI

Group Inc. and President of its ID Business Company

“The Evolution of MISUMI's Manufacturing"

Takumi Toya,

Representative Director and President,

Suruga Production Platform Co., Ltd.

<Factory Tour>

<Factory Tour>

By observing both the conventional MISUMI Production System and the meviy production system, the attendees witnessed the evolutionary process of MISUMI's digital manufacturing. They also received detailed explanations from on-site officers in front of each facility inside the factory.

The meviy Digital Manufacturing System, in which unmanned production lines operate, can generate machining programs, transport materials, and process them by intelligent automation. Upon entering the pristine white factory, the attendees were amazed and let out a wow. They enthusiastically asked questions throughout the tour.

▼ A Special Webpage for "the meviy Digital Manufacturing System"

▼ A Special Webpage for "the meviy Digital Manufacturing System"

In the video, you can see inside the factory where the parts ordered via meviy are produced, and some of the mechanisms of digital manufacturing.

The MISUMI Production System

(ALASHI STADIUM)

Line where materials are automatically cut out by water jet

(the meviy Digital Manufacturing System)

<Critiques by experts and representatives from companies using meviy>

<Critiques by experts and representatives from companies using meviy>

Takahiro Fujimoto, Professor at the Institute for Business and Finance, Waseda Business School

Takahiro Fujimoto, Professor at the Institute for Business and Finance, Waseda Business School

Title: “A Story in Three Acts: MISUMI's Design Innovation, Production Innovation and meviy”

For the first time in 30 years, Japan's manufacturing industry has entered an era in which raising productivity levels is essential. In the digital age, Japan has traditionally excelled in manufacturing products of integral product architecture. meviy, a procurement platform for custom products, offers a clue on how to overcome the potential weaknesses of such manufacturing. Following MISUMI's "catalog standardization" and "realization of global, reliable, and quick delivery of made-to-order products based on model numbers," "meviy, a digital manufacturing system that directly links 3D design data to AI quotations for same-day shipping," is the third act in MISUMI's story of design innovation and digital manufacturing innovation. I was thrilled to witness this at today's Factory Day. I look forward to seeing it develop in the future.

Mr. Takatoshi Morimitsu,Senior Manager, Technical Planning Office,Monozukuri Engineering Department,Toyota Motor Corporation

Mr. Takatoshi Morimitsu,Senior Manager, Technical Planning Office,Monozukuri Engineering Department,Toyota Motor Corporation

In this factory, the motto of “4S” (“organize, keep things neat and clean”) is thoroughly implemented.

Designers focus on how to eliminate waste in design and spend more time on what is newly created. In this regard, meviy is an excellent educational tool that provides immediate answers.

In terms of production, I could see that they are thoroughly committed to lead time reduction, which is also the basis of the Toyota Production System (TPS). Here in this factory, "optimal intelligent automation" is in progress, and today’s experience will be a good reference for me in designing future manufacturing production systems.

Mr. Masato OtsuboPresident and Representative Director,Yuki Holdings Co., Ltd.

Mr. Masato OtsuboPresident and Representative Director,Yuki Holdings Co., Ltd.

The percentage of our company's internal use of MISUMI has been steadily increasing, and our engineers are happy to use meviy. As a technical advisor, I used to attend the monthly meetings of meviy before the service was launched. Today, I was very impressed to see that what I had dreamed of 8 years ago has become a reality. At this rate of development, I expect to see an incredible level of intelligent automation in manufacturing in 10 years or even a few years.

Person in charge of machinery design for a major American EV manufacturer

Person in charge of machinery design for a major American EV manufacturer

(He flew from Germany for this event.)

We have been working with MISUMI for over 12 years and find their recent efforts to be excellent. We use meviy in Berlin and it has made our work very efficient. The advantage of meviy is that it has revolutionized our engineering time, allowing us to spend more time on more important tasks. We recently designed a large machine tool and were able to procure more than 90% of the parts in a very short time using MISUMI and meviy. The fact that they can machine and deliver precise parts with a high degree of reproducibility is also excellent.

Comments from Attendees

Comments from Attendees

Here are some of the comments we received from the media who attended the event.

“I never imagined that digital manufacturing had come this far. It must have taken an extraordinary effort to bring the manufacturing site of a one-of-a-kind product, or a variable mix and quantity production so close to standardization."

“It was a great learning experience for me to see once again the greatness of MISUMI, which cannot be replicated by others."

“A wonderful event. I was amazed that my wish to see something like this became a reality.”

What is meviy?

What is meviy?

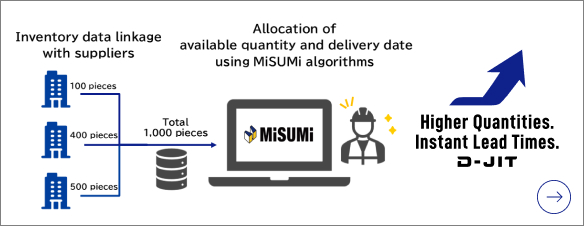

With meviy, customers simply upload a 3D model of a mechanical component, the AI automatically provides an instant quote, and our unique Digital Manufacturing System enables an order to be shipped in one day at the earliest.

With meviy, customers simply upload a 3D model of a mechanical component, the AI automatically provides an instant quote, and our unique Digital Manufacturing System enables an order to be shipped in one day at the earliest.

meviy received the Prime Minister's Prize at the Ninth Monodzukuri Nippon Grand Awards, achieved the No. 1 market share in Japan for three consecutive years, and is highly regarded for its contributions to improving productivity in the manufacturing industry. For our global customers, the range of services on each meviy website is expanding. meviy delivers "time value" to customers worldwide through digital transformation in component procurement.

What is MISUMI?

What is MISUMI?

MISUMI sells mechanical components required on-site for factory automation, as well as tools, consumables, and other products to more than 320,000 companies* worldwide. We wear two hats: a manufacturer with manufacturing functions and a distributor of other company’s branded products. With this unique business model, supported by a solid business base, MISUMI achieves "globally reliable, quick delivery" for greater customer convenience. (* As of March 2023)

For inquiries regarding this press release, please contact

Matsubara, Corporate Relations Department MISUMI Group Inc.

- Tel

-

03-6777-7502

MISUMI's e-Commerce Site

We supply custom parts for automation devices and equipment, dies/molds, tools, consumables, and more, with same-day shipping at the earliest. Products from more than 3,000 domestic and international third-party brands, including MISUMI, are offered.