The following is an introduction to environmental initiatives being taken by MISUMI Group

Initiatives at Production Sites

Initiatives at Production Sites

SURUGA Production Platform, as a global company, is responsible for MISUMI Group’s production and is firmly aware. firmly aware of its social responsibilities and has agreed to comply with environment-related laws and regulations, and other requirements. We contribute to building a sustainable society by promoting environmental activities such as decarbonization, under the slogan “Coexistence of Technology and Ecology”.

Environmental policy

Environmental policy

- 1.

-

Compliant to environmental laws, regulations, and other requirements both domestically and

internationally

- 2.

-

Acceleration of energy creation/energy saving to achieve carbon neutrality by 2050

- 3.

-

Initiatives to minimize and recycle waste

- 4.

-

Reducing environmental impact in product development and production activities

- 5.

-

Prevention of environmental pollution

- 1)

-

Prevention of leakage of oils and harmful substances

- 2)

-

Prevention of noise leakage from the site boundary

Environmental management

Environmental management

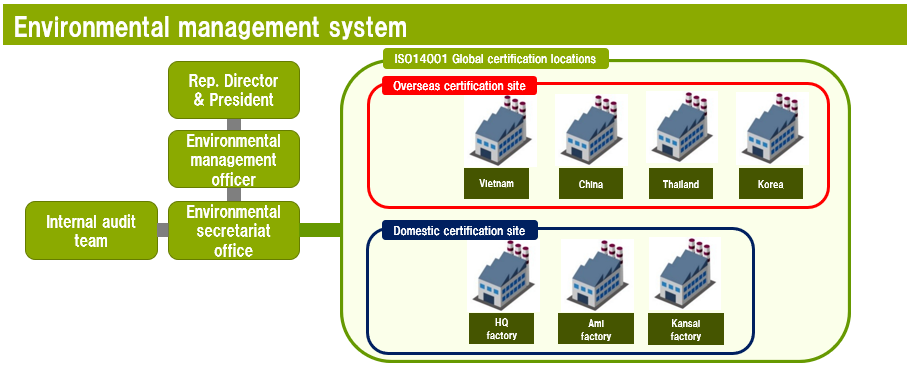

Environmental administrative structure

Environmental administrative structure

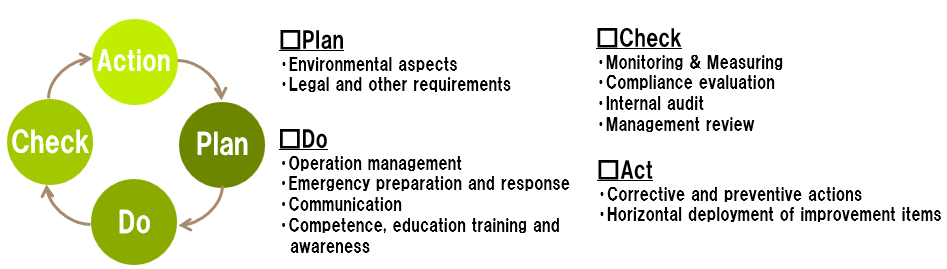

Environmental PDCA

Environmental PDCA

Environmental Committee

Environmental Committee

To promote practical environmental improvement activities, the Environmental Committee regularly holds meetings and shares environmental activity policies, environmental management KPIs, and plans and achievements of environmental improvement activities to strengthen our environmental management.

Internal audit・External audit

Internal audit・External audit

To confirm the operational status and effectiveness of our Environmental Management System and horizontally deploy best practices in environmental activities, we conduct an internal audit annually and undergo an external audits by the ISO 14001 certification body. The results of both internal and external audits reported to the Environmental Committee, contributing to the continuous improvement of our Environmental Management System.

Environmental education

Environmental education

In line with our environmental education and training plan, we provide environmental education to our employees. Additionally, to enhance our environmental management structure, we conduct regular training activities such as annual internal audit sessions, with a focus on on-site managers.

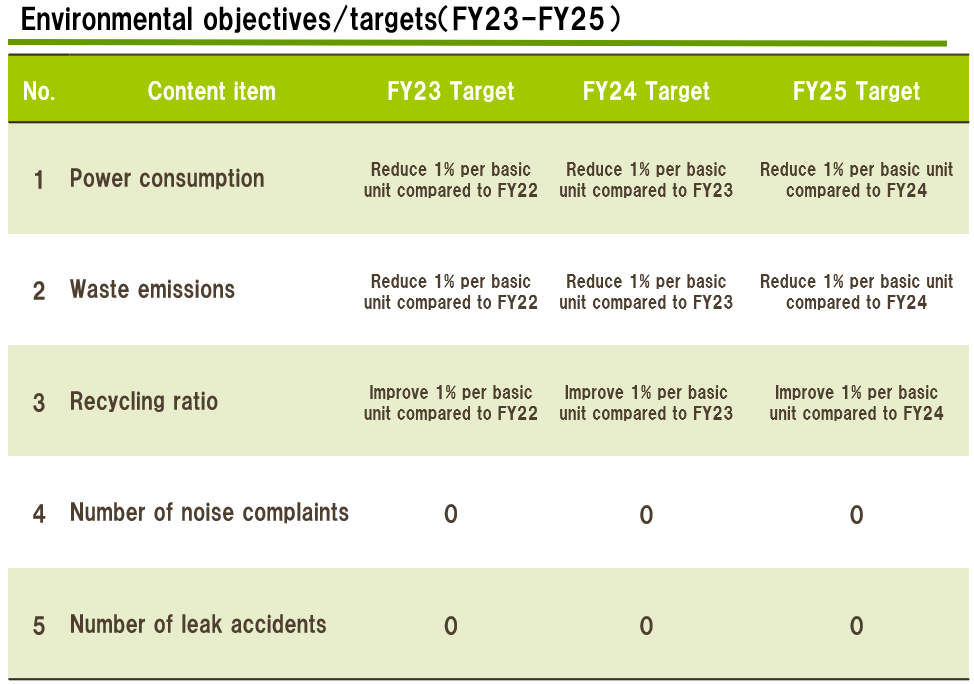

Environmental objectives/ targets

Environmental objectives/ targets

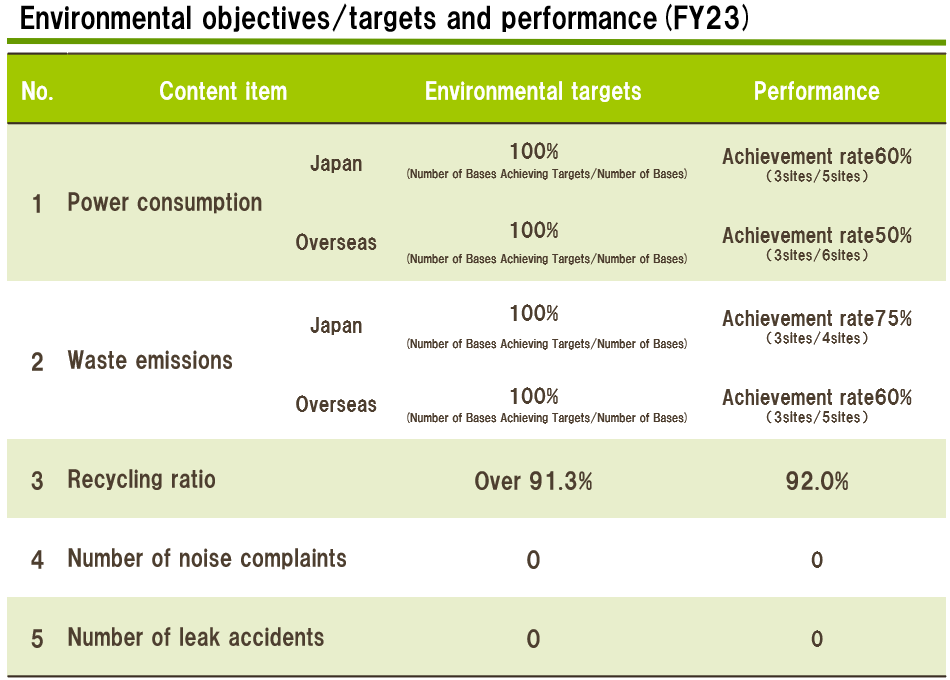

Environmental objectives/targets and performance

Environmental objectives/targets and performance

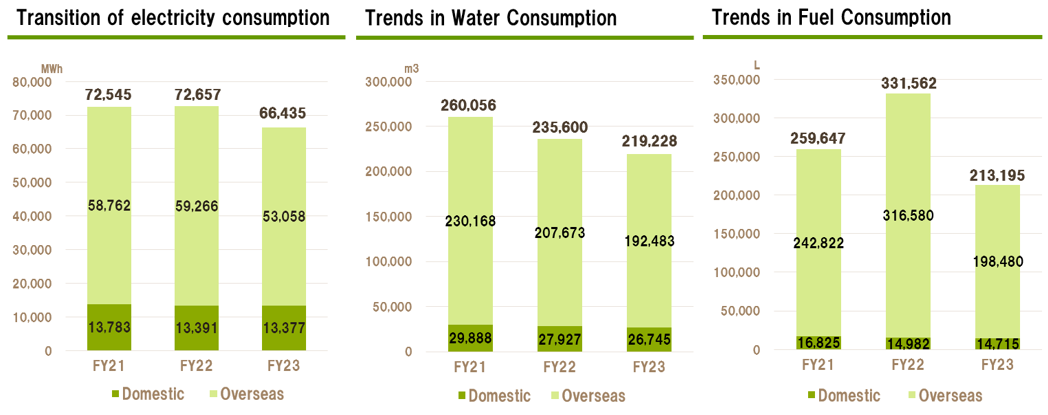

Changes in the environmental impact associated with business activities

Changes in the environmental impact associated with business activities

INPUT

INPUT

OUTPUT

OUTPUT

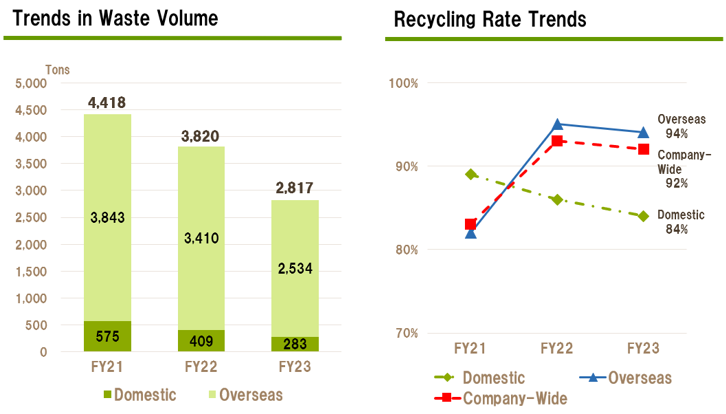

Achievement of Energy Creation Measures

Achievement of Energy Creation Measures

Nantong, China: Operations began in FY17, panel expansion was completed in 2022, and FY23 was power generation deteriorated by 8.9% due to weather conditions.

Vietnam: Operations began at the factory 4 during FY22, expansion work was conducted at the factory 4 in FY23, and installation was carried out at the factory 3, resulting in a 140.4% improvement in solar power generation compared to the previous fiscal year.

Vietnam

Nantong, China

Examples of Initiatives

Examples of Initiatives

Efforts towards a deoxygenated society

Efforts towards a deoxygenated society

Initiatives for the 2023 fiscal year

・CO₂-free electricity has been introduced in all domestic factories

・At the Shimizu Factory, the introduction of an automatic air conditioning control system has reduced the power consumption of air conditioning units by approximately 14%

・In February and March 2024, solar power panels will be added within the factory premises at the Vietnam factory to accelerate CO₂ reduction2024

Reduction of waste emissions

Reduction of waste emissions

To promote recycling, waste is properly separated, and the company-wide recycling rate is maintained at over 90%. We are also working on introducing new equipment and making process improvements to reduce the loss from defects that occur during the manufacturing process

Compliance with the RoHS Directive / Green Procurement

Compliance with the RoHS Directive / Green Procurement

In order to comply with the RoHS Directive and Green Procurement Guidelines, our company investigates restricted and prohibited substances in materials and components for each business and promotes substitution.

For example, we aim for compliance by substituting low-cadmium materials for brass components incorporated into precision positioning stages. In conjunction with custom product support, we are planning the sequential sale of compliant products.

Furthermore, recognizing the conservation of the global environment as the most important issue for the Earth, we will act with sincere consideration to preserve and enhance the global environment in our corporate activities.

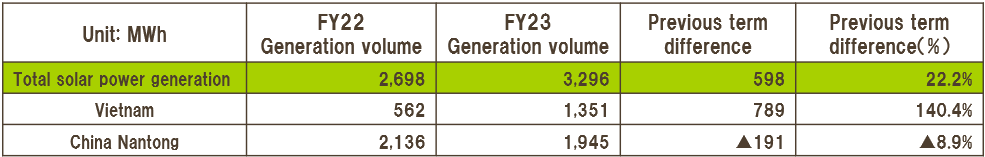

ISO14001 Certification Status – Suruga Production Platform

ISO14001 Certification Status – Suruga Production Platform

Suruga Production Platform has obtained ISO14001 certification at domestic and overseas manufacturing sites.

| Business name | Suruga Production Platform Co., Ltd. |

| Certified production sites | Shimizu Factory, Ami Factory, Kansai Factory, Saigon Precision Co. Ltd. (“SPC”) No’s. 1, 2, 3 and 4 Factories (all factories certified), Suruga Korea (FA/ OST), Suruga Shanghai (Die and Mold/ OST), Suruga Thailand (Die and Mold) |

| Certifying company | Bureau Veritas Japan Co., Ltd. |

| Certification number | 4715763 |

| Registration date | January 2001 |

Introduction of CO₂-free Electricity

Introduction of CO₂-free Electricity

In April 2022, we implemented CO₂-free electricity* at seven locations, including the head office of the SURUGA Production Platform. Consequently, we reduced greenhouse gas emissions from our manufacturing sites in Japan approximately 6,500 tons in FY2023. This is equivalent to 9.7% reduction of Scope1 and 2 GHG emissions of our entire group in FY2020, the base year.

- *

-

Electricity with CO₂-free value derived from renewable energy power sources that do not emit CO₂ during power generation

Details on the Introduction of CO₂-free Electricity:CO₂-free electricity sold by Chubu Electric Power Miraiz Co., Inc., CD Energy Direct Co.,Ltd. and The Kansai Electric Power Company, Incorporated

Sites where we have Introduced CO₂-free Electricity (six sites):

SURUGA Production Platform Co., Ltd.

Head Office:505 Nanatsushinya, Shimizu-ku, Shizuoka City, Shizuoka

536 Nanatsushinya, Shimizu-ku, Shizuoka City, Shizuoka

549 Nanatsushinya, Shimizu-ku, Shizuoka City, Shizuoka

Kansai Factory:2-3-2 Akamatsudai, Kita-ku, Kobe City, Hyogo

Ami Factory:3-2 Hoshinosato, Ami-machi, Inashiki-gun, Ibaraki

Mishima Seiki Co., Ltd:580-49 Tokura, Shizmizu-cho, Sunto-gun, Shizuoka

Reduction in GHG emissions: Approximately 6,500 tons a year

We are participating in the Shizuoka Prefecture Renewable Energy Electricity Utilization Promotion Project which promotes introducing of 100% renewable energy in Shizuoka Prefecture.

Initiatives in Logistics

Initiatives in Logistics

To reduce greenhouse gas (GHG) emissions in logistics, we are taking proactive measures by introducing EV vehicles to some of our delivery routes in Central Japan. Furthermore, we are optimizing logistics routes nationwide and transitioning some international shipments from air to sea freight to further lessen our environmental impact.

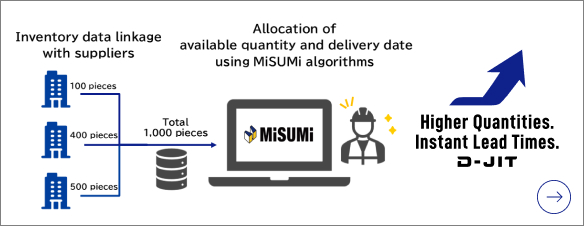

MISUMI's e-Commerce Site

We supply custom parts for automation devices and equipment, dies/molds, tools, consumables, and more, with same-day shipping at the earliest. Products from more than 3,000 domestic and international third-party brands, including MISUMI, are offered.